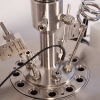

反應器容積: 100 - 600 ml

壓力:-1 (FV)- + 400 bar

溫度:-20 ° C - + 400 ° C

材料: 不銹鋼、 哈氏合金

這是我們新的高溫高壓反應釜 novoclave。該高壓反應器專為高溫高壓的反應程序設計。其安全功能可以確保在最高壓力下安全的進行反應。該設備根據PED, AD2000 所設計、製造及測試。內建電熱器和自來水冷卻系統,可自動快速精準地控制溫度。可編成PID控制器,可直接在設備上或通過電腦操作。

novoclave具模組化的設計,允許在相同的上蓋和加熱器下改變反應器容量,從100ml至600ml。

有以下幾種容量可供選擇:100/200/300/450 / 600ml。

即使改變容器容量,依然維持最佳幾何形狀(長度直徑比例)

不銹鋼或Hastelloy®反應器可確保高耐腐蝕性。磁力攪拌器確保反應過程得以有效混合和優異的熱傳導。

Reactor volume: 100 - 600 ml

Pressure: -1 (FV) to +400 bar

Temperature: -20 °C to + 400°C

Material: stainless steel, (Hastelloy® +400°C)

High-Pressure Version:

Reactor volume: 100 - 600 ml

Pressure: -1 (FV) to +500 bar

Temperature: -20 °C to + 500°C

Material: stainless steel, (Hastelloy® +400°C)

This is our new high pressure and high temperature autoclave novoclave. This high pressure reactor system is designed for processes involving high pressures and temperatures. Safety features guarantee safe reactions under highest pressure. Designed, manufactured, and tested according to PED, AD2000. Electrical heating with built-in automated tap water cooling for fast and precise temperature control and programmable PID controller for operation at device or via PC.

The modular setup of the novoclave system allows for changing the vessel size from 100ml up to 600ml using the same cover plate and electric heating block. Vessels are available in the following volumes: 100 / 200 / 300 / 450 / 600ml. Despite changing vessel sizes, the optimal vessel geometry (i.e. relation between diameter and length) is maintained.

The stainless steel or Hastelloy® reactors ensure high corrosion resistance. The magnetic stirrer drive ensures efficient mixing and stirring of the process media as well as excellent heat transfer.