玻璃-玻璃襯裡鋼反應器: 15、 30、 60、 100、 160、 250liter

工作壓力: -1.0 (FV) - +0.5 bar

工作溫度:-60 ° C (-90 ° C) - + 200 ° C

材料: 硼矽酸鹽玻璃 3.3,搪玻璃、 聚四氟乙烯、 PFA、 鉭

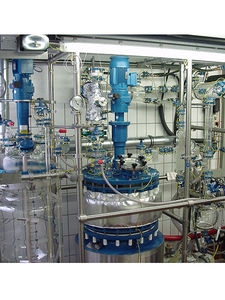

Buchi 玻璃反應系統在防爆設計上的關鍵問題有著高性能和可靠性。惰性材料可以保障在完全真空條件下密封的玻璃反應體系中的溶劑和酸以及種類繁多的惰性氣體的處理的安全。同樣的設備配置可以安全地執行多種化學反應步驟。

該系統包括 :反應釜體為堅固的搪玻璃材料,可提供優良的傳熱,穩定的工藝條件和溫度,其中玻璃部分可通過目測來監控化學反應。蒸餾玻璃部分由 buchiflex 元件 (獨特靈活球-套連接關節) 組織架構,構建可靠的完全真空條件過程。

CR 類型 chemReactor 是化工過程開發、 規模發展、 過程類比和 cGMP 公斤生產批量和半間歇式操作的多功能試驗反應器系統。

我們提供化學加工的完整解決方案: 反應器系統包括像取樣裝置、 ph 值探頭、精餾填料及配件、 過程監測和控制以及輔助設備,如溫度控制單元,nutsch篩檢程式 / 乾燥機、 洗滌器或混合槽。

Glass-, glass lined steel reactor: 15, 30, 60, 100, 160, 250 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60 °C (-90°C) to +200 °C

Material: Borosilicate glass 3.3, glass lined steel, PTFE, PFA, Tantalum

- Hastelloy, other materials, other designs on request

Performance and reliability are key issues in the explosion proof design of Buchi glass reaction systems: The inert materials allow safe processing in a inert atmosphere of a wide range of solvents and acids in a completely sealed glass reaction system under full vacuum. Multiple chemical reaction steps are performed safely in the same setup. The system consists of:

Reactor with solid jacketed glass lined steel bottom stands for solid construction, excellent heat transfer, stable process conditions and temperatures, and a glass section to easily improve and control chemical reactions by visual observation.

Distillation glass overhead built with buchiflex components (unique flexible ball - socket joints) for mulitple, reliable processes under full vacuum.

The CR type chemReactor is a multipurpose pilot reactor system for chemical process development, scale-up, process simulation and kilo-scale cGMP production in batch and semi-batch operation.

We produce complete solutions for chemical processing: Reactor systems including accessories like sampling devices, pH probes, rectification columns with structured packing, process monitoring and control as well as integration of auxiliary equipment such as temperature control units, nutsch filters / dryers, scrubbers or mixing vessels.

Standard options

- Reactor lift for easy opening (vessel cleaning)

- Sampling device

- pH monitoring and control

- Gas introduction (Nitrogen purging and active gas)

- Vacuum / exhaust piping

- Additional feeders / receivers

- Solid feeding

- Cryogenic vessel for low temperature chemistry (-90°C)

- in special glass lining or Hastelloy C22

- mixed systems with pressure reactor and vacuum distillation

- IQ / OQ / PQ